Automation in material handling is playing a more important role in the current days and will keep growing in the future. A report from Logistics IQ showed that the warehouse automation market will reach USD27 billion by 2025. And we believe that the market demands on AGVs will keep accelerating with the impact of COVID-19 as people can benefit from safe, health and reduce social contact.

With nearly 50 years of experience in forklift R & D and manufacturing, Hangcha, now the China’s top three in AGV forklifts, enjoys a domestic AGV market share of 10%+. Currently, We have 6 series of more than 30 products, namely the pallet mover series, including 3t pallet AGV, 2t stacking AGV, and 3-5t stacking AGV; the high-level reach series, including 2t reach AGV and VNA three-directional reach AGV; Also the load transfer AGV, the traction series and the mini series. More than 200 Hangcha AGV forklifts projects have been landed, varied from photovoltaic, automotive, 3C electronics, rubber, logistics, to pharmaceutical industries at home and abroad. Our customers include Bekaert, Shenyang BMW, Shanghai Volkswagen, Blue Dragon Logistics, Cainiao Logistics, Zcrubber, LONGi Solar, and many more. According to our customer feedbacks, our AGV solutions greatly reduce the deployment cost and time and the highly flexible solution always surprise them.

Reach Truck AGVs & Stacking AGVs for Ningbo Blue Dragon Logistics

2t Stacking AGVs for Hangzhou Chaoyang Rubber

AGV Solutions for other customers in varied industries

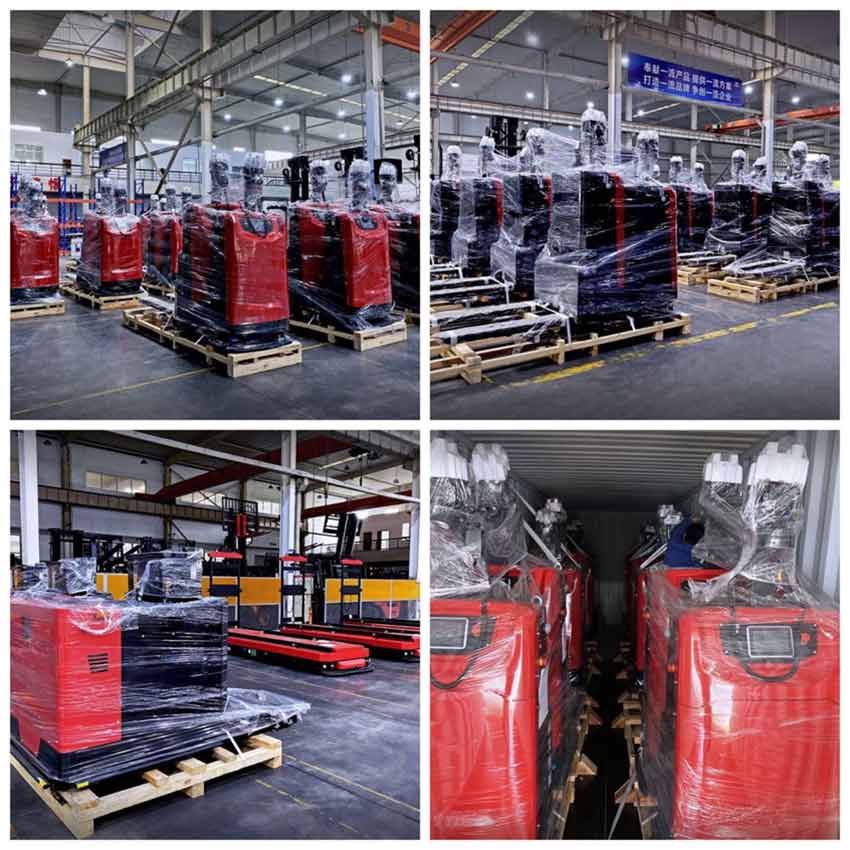

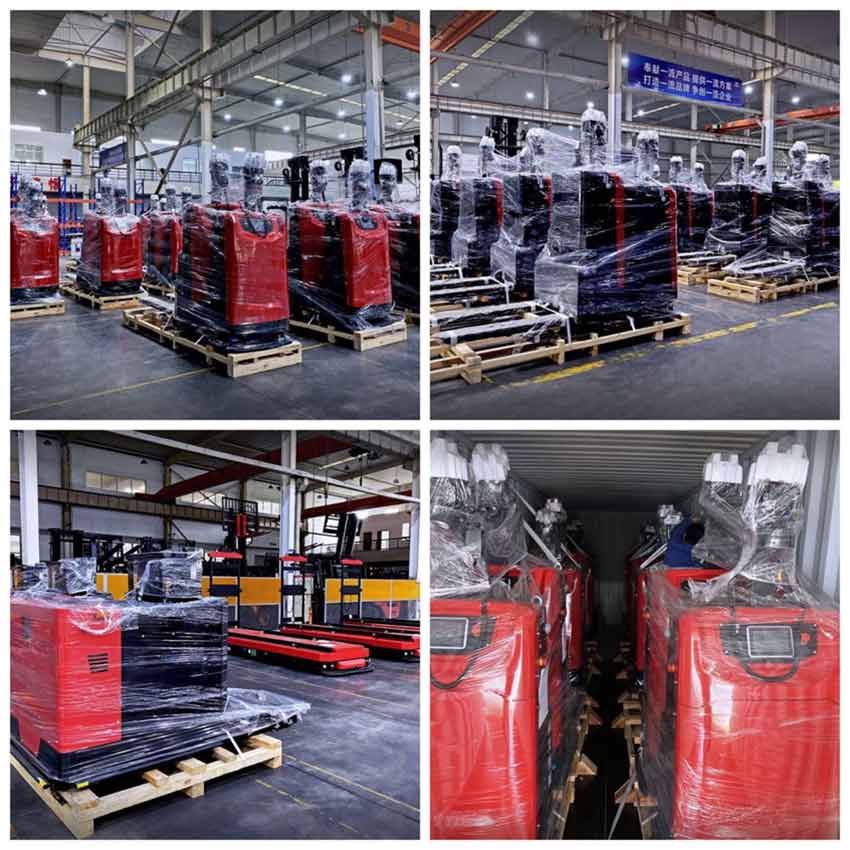

Recently, we just delivered 22 units 2T mini-stacking AGVs, 3T heavy-duty stacking AGVs, 3 units 4.5T Flatbed AGVs, a total of 28 Hangcha AGVs, to a well-known enterprise of tire industry in Vietnam. Here are some details you may be interested.

28 units AGVs just be delivered to a Vietnam customer

Brief introduction of the customer:

The customer is a famous enterprise in Vietnam that focus on researching and producing a complete fleet of commercial tires varied from truck tires to engineering machinery tires etc. It is listed in the top 75 tire manufacturing enterprises in the world.

Industry:

Manufacturing enterprise

Our solutions:

2T mini stacking AGV+ 3T heavy stacking AGV+ 4.5T Flatbed AGV+MES system +WMS system + intelligent charging pile.

And in this project, the 2T mini-stacking AGV plays a very important role. It is a perfect option for logistic center, warehouse and factory etc. With a compact design, its right-angle stacking aisle width is 2.2 m, reducing 19% aisle requirement and enjoying high control precision at the same time. In addition, it saves about 30% energy consumption and provide higher working efficiency.

2T mini-stacking AGV

Working process:

We integrated mechanical arm, conveyor line, shuttle, baler, WMS, AMS and other hardware and software to make the overall planning of the project. In the AGV software, there are three layers, in which the MES and WMS systems of the upper layer are connected through AMS, and the production line, elevator, automatic door, AGV and other equipment of the execution layer are scheduled.

.jpg)

Working process

Highlights of this project:

Overcoming the complicated overseas procedures, prolonged transportation time and other difficulties under pandemic.

The compact design makes it flexible in the narrow aisle and adapt to the high requirements of control precision.

It has broken through many technical difficulties such as elevator docking and AGV automatic empty pallet stacking. It adopts SLAM natural navigation for various docking of production line and storage location, replacing the original operation mode of manual vehicle, minimizing manpower, increasing efficiency and realizing the overall logistics intelligence.

Intelligent storage location management with instant feedbacks from the system can prevent high manual code scanning errors and omissions that happened often in the past.

These 28 AGVs will be arrived soon and we will keep follow the feedbacks from our customer and provide our best service. As the top 8 forklift manufacturer in the world, Hangcha has become the super golden partner with NDC and able to you provide you customized solutions in competitive price. We have more cases you may be interested and you can follow “Hangcha forklift” on Facebook and Youtube or download “Hangcha forklift” App on Google Play or from App or Android store.

.jpg)

Download “Hangcha Forklift” App, Hold Hangcha In Your Hands.

.jpg)

.jpg)